Gavà’s company shines nowadays in numerous pages of prestigious and international magazines. The last one has been the extended report written by Robin Bradley for the International Dealer News, the leader magazine about motorbike sector in English language.

“Their R&D, testing and quality control processes and procedures are among the most extensive and exhaustive I have seen in any motorcycle parts and accessory business”, wrote the experimented journalist in his report. Where he adds: “In the past 25 years I care to try to count, literally, hundreds of companies where I had been”.

This is the way Robin Bradley starts to give his opinion about J.Juan Group in an extended four pages report –including a mention also on the cover- which has been published in the most read edition of the year of the prestigious international magazine of the motorbike sector. The chief editor of the International Dealer News and the American Motorcycle Dealer visited J.Juan’s factory in Gavà (Barcelona in July, when he toke advantage of the situation to know about the facilities, the procedures, the way of work and the growth of the company. Badley had a talk with Jose Luis Juan, CEO of the enterprise, who confessed: “The key has been the vision of the future, trying to detect and anticipate problems and opportunities through our continuous investment in research and development”.

In the last August edition, the English magazine also remarked the unstopped work J.Juan is carrying out actually, researching and planning its entry in the brake caliper market during the last 10 years. Until now, J.Juan is recognized as the whole leader in hydraulic brake and clutch hoses. International Dealer News remarks the Spanish company already produces ‘tailor made’ brake systems available for different types of bikes. Robin Bradley writes as a headline and also he repeats in the report that J.Juan Group not only homologue its products but also its procedures. “Today our brake calipers and control products have more than 200 validation stages, tests and checks before being installed on a motorcycle”, could be read it in words of Jose Luis Juan. With no doubts, one of the main points that explain the prestige of J.Juan Group.

This is the way how the International Dealer News’s report starts:

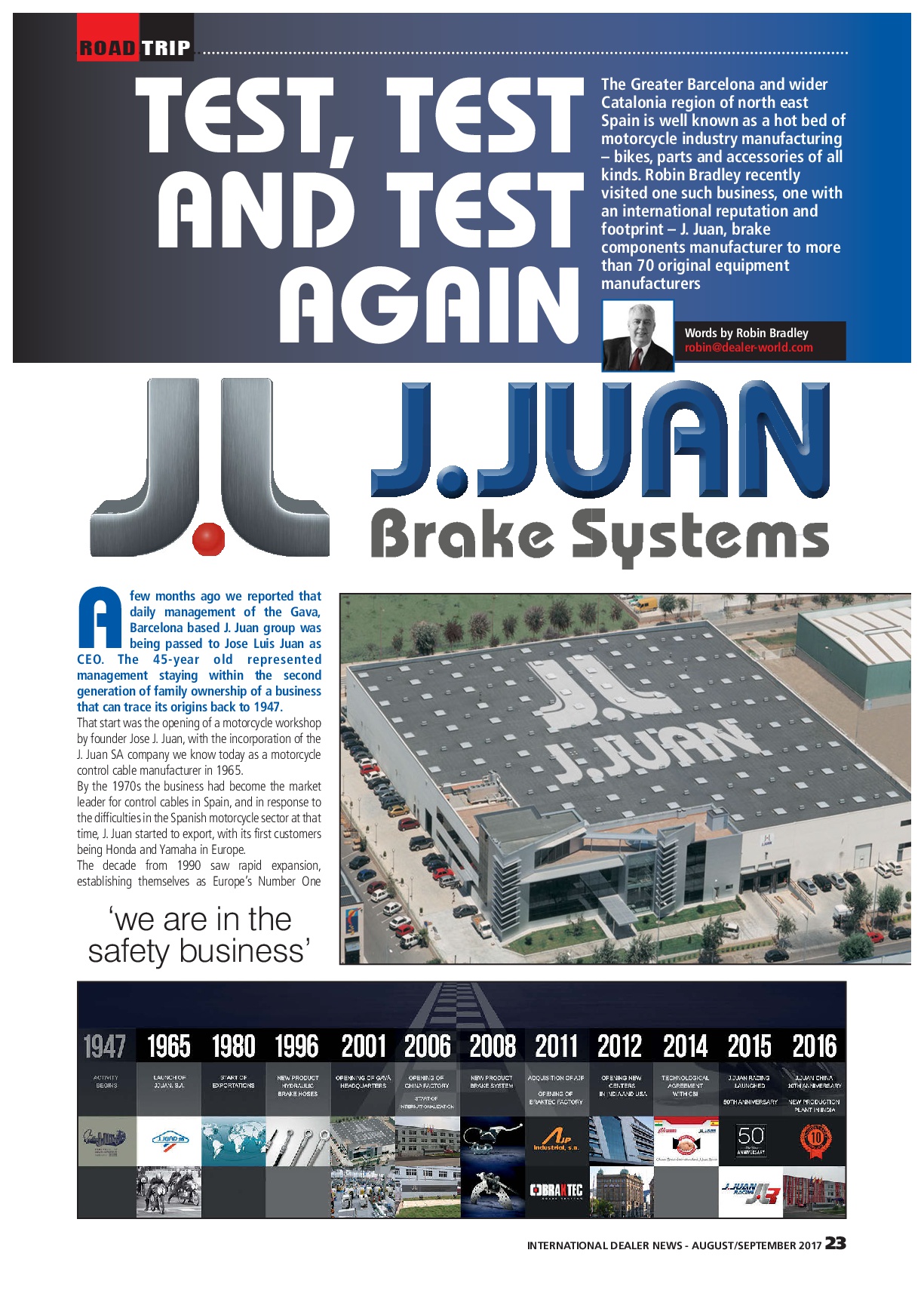

TEST, TEST AND TEST AGAIN

The Greater Barcelona and wider Catalonia region of north east Spain is well known as a hot bed of motorcycle industry manufacturing – bikes, parts and accessories of all kinds. Robin Bradley recently visited one such business, one with an international reputation and footprint – J. Juan, brake components manufacturer to more than 70 original equipment manufacturers.

A few months ago we reported that daily management of the Gava, Barcelona based J. Juan group was being passed to Jose Luis Juan as CEO. The 45-year old represented management staying within the second generation of family ownership of a business that can trace its origins back to 1947. That start was the opening of a motorcycle workshop by founder Jose J. Juan, with the incorporation of the J. Juan SA company we know today as a motorcycle control cable manufacturer in 1965.

By the 1970s the business had become the market leader for control cables in Spain, and in response to the difficulties in the Spanish motorcycle sector at that time, J. Juan started to export, with its first customers being Honda and Yamaha in Europe.

The decade from 1990 saw rapid expansion, establishing themselves as Europe’s Number One control cable manufacturer with particular success in Italy with manufacturers such as Piaggio, Aprilia and Ducati.

‘We are in the safety business’

Because of the evolving technology of motorcycle brakes, J. Juan entered the flexible hose sector in the 1990s, and the same quality control focus we still see today resulted in their first ISO 9001 Certification. European brake hose market leadership happened quickly, and the next stage for J. Juan was to be able to start being able to supply the complete brake system, from levers and master cylinders, through cables and hoses to the calipers themselves.

These days Europe accounts for some 50 percent of sales, with 30 percent in America and some 20 percent in Asia. Still headquartered at Gavà, on the coast just south of Barcelona, expansion is underway in the region with an additional facility added to the group, and internationally with wholly owned or partnership factories in China and India, a U.S. office in Milwaukee, Wisconsin, and a factory to service their growing American sales, especially in the ATV/Quad and UTV/SxS markets, due for completion in Mexico in 2018.

The company’s OE customer roster is impressive, with customers from right across the powersports industry spectrum, from small cc, scooters and trails bikes, through to big inchers, the Quad/ATV and UTV/SxS sectors, even including a growing number of electric vehicle manufacturers. From Rieju and Gas Gas in Spain, to BMW, Ducati, Triumph, Husqvarna, KTM, Piaggio, Moto Guzzi, Peugeot, Aprillia, MV Agusta, Govecs, Domino, Magura and others elsewhere in Europe; to Yamaha, Honda and Suzuki in Japan; Hyosung, Loncin, Mahindra, Kymco, Quadro, Zongshen, CF Moto and Hero in India and elsewhere in Asia; through to the likes of Polaris, BRP, Can-Am, Indian Motorcycle, Ski-Doo, Arctic Cat and Zero Motorcycles in the United States and Canada.

J. Juan says it is the second largest manufacturer of brake components in Europe and that 90 percent of “Western” manufactured motorcycles have at least some J. Juan brake components on them – in 2015 alone the company invested some 1 million euros into brake component R&D. Therein lies the heart of the J. Juan story.

As I saw for myself on my recent visit to their Gava, Barcelona factory, their R&D, testing and quality control processes and procedures are among the most extensive and exhaustive I have seen in any motorcycle parts and accessory business I have ever seen – and I have visited manufacturing plants of more kinds in more countries in the past 25 years than I care to try to count, literally hundreds.

Their Internal Validation Procedures have built-in redundancy and double or triple checks for every stage. As CEO Jose Luis Juan says “we are in the safety business. Where safety is concerned you just cannot invest in too many ways of making sure that the product we ship to our customers not only lives up to our reputation, but theirs too.

“Original Equipment manufacturers will supply-side source product from a company such as ours specifically because we can supply a better and more reliable product than they can, and because we can deliver it cost effectively. We can do so, compared to an OE factory, because our investments are spread across such a wide range of applications and higher volumes than they can ever leverage themselves.

‘We don’t just homologate the product, we homologate the process’

“At J. Juan we don’t just homologate the product, we homologate our processes too – design, materials, testing, manufacturing, more testing and quality control procedures are subjected to the most intense scrutiny, so we can achieve ISO accreditation for the process.”

Brake hoses are some 60 percent of their business, and among the many proprietorial hallmarks of J. Juan’s manufacturing, they identify the hose joint and crimping as they key to hose reliability and therefore braking safety.

The company has developed, invented and tooled their own designs of test rigs to put their processes to proof to levels way beyond those that any motorcycle hose, or other brake component, will ever be required to meet. The challenge with hoses, Jose Luis explained, is to design and then be able to also make them simultaneously hard and flexible; ensuring the integrity of each component and the assembly, and ensuring there is no evaporation of loss under pressure or the heat that braking energy generates.

“I am proud to be able to say that we have become the world leader in the manufacture of hydraulic brake and clutch tubes for motorcycles, and we believe that a lot of the reason for this is the understanding that our validation procedures have given us of the dynamics of braking systems.

‘We have become the world leader in the manufacture of hydraulic brake and clutch hoses’

“When you tighten the brake or clutch lever, the pressure is transmitted through hydraulic pipes. Initially these were made from rubber, and still are on some Japanese made motorcycles. However, with heat the rubber expands and this affects the “feel” that the rider gets, and it affects the performance of the brake or clutch as a system. We invested two years into inventing our own patented system of braided hose that allows the “feel” to be constant, consistent and progressive – transmitting a sense of security, reliability and predictability to the rider.

“One of the best of recent credentials we had of this improved braking performance came through our work with Tom Sykes and Jonathan Rea and their Kawasaki World Superbike Championship bikes. The innovation, backed up by our proprietary crimping solutions that prevent any kind of leakage, got the attention of the manufacturers. BMW for example use our system on all their production bikes.

“Since these initial innovations we have been able to evolve continuous improvements almost exponentially – especially where ABS are concerned. Proper and reliable operation of ABS systems place a premium on the reliability and precision of the feedback that the motorcycle ECU receives.”

During the recession J. Juan bucked the trend by maintaining is R&D investments and activities and continued to grow as a result. The company currently has over 450 workers, 80 percent of them in their Spanish factories.

“The key has been the vision of the future, trying to detect and anticipate problems and opportunities through our continuous investment in research and development, and planning to meet them.”

That investment hasn’t only been in-house. We will leverage the skills, expertise, experience and resources of partners – partners such as the IK4-IDEKO Technology Center, a world renowned industrial production, manufacturing technology hub in northern Spain whose scientific excellence has made them a European reference for industrialization with a portfolio of more than 1,500 private industry clients.

“Our reputation for high quality, efficient manufacturing and cost-effective production with zero errors has in turn made J. Juan the reference in the brakes sector. In fact, when CBI – Bosch’s former automotive braking division – decided to get into manufacturing motorcycle brakes, it established a technology transfer agreement with J. Juan – we are providing the technical know-how and production processes for the CBI factory in India that has allowed us to gain entry to the fast-growing and rapidly developing motorcycle component industry there.”

‘The company has developed, invented and tooled their own designs of test rigs’

CBI (Chassis Brakes International) is an American backed multinational based in Paris; with 15 factories around the world the company is one of the largest of all brake manufacturers, supplying most of the best known automotive majors. J. Juan actually spent some 10 years researching and planning its entry in the brake caliper market before pulling the trigger on expanding into being able to offer its customers a complete braking system capability – but since that trigger was pulled their success has been remarkable, their growth rapid.

“We spent 10 years researching our entry in that market. Researching materials, machinery, deigns, trends, a suitable supplier base, acquiring some smaller companies and focussed on continuous improvement analysis. Above all we wanted to be sure we could have the same degree of design integrity and quality control that had built our reputation, and today our brake calipers and control products have more than 200 validation stages, tests and checks before being installed on a motorcycle.

“We started with the Trials market because where brakes are concerned, that is probably the toughest test there is. Control over the brakes and dependable precision brake operation is at the very heart of the sport. We established Braktec in 2011 as a Trials and Offroad specialty division and brand, following our acquisition of AJP, and now also have a speciality J. Juan Racing division for our on-road caliper businesss, and both divisions are able to draw on the same resources – the same tooling capacity, engineering, laboratory and production process back-up. Already, after just five years, Braktec is the benchmark brand in its markets – over 90 percent of Trials bikes, for example, are ex-factory with Braktec brakes. We think the future is only positive for our company,” Jose Louis concludes. “The direction of travel in the transport industry in particular, and in the motorcycle industry in particular, speaks to our core competencies.

We expect to continue to grow in the coming years as more and more manufacturers look to leverage our experience and expertise, our R&D investments and, especially, our knowledge of CBS and ABS.

“We think the motorcycle industry, and wider international powersports industry, will continue to grow, continue to diversify, and we think J. Juan is in a perfect position to continue to be a premium player in the industry developments that lie ahead.”

Here you will find the complete report in English.